CATHODEX EQUIPMENT

We have two types of equipment, that is used based on customer´s needs and plate requirements:

-

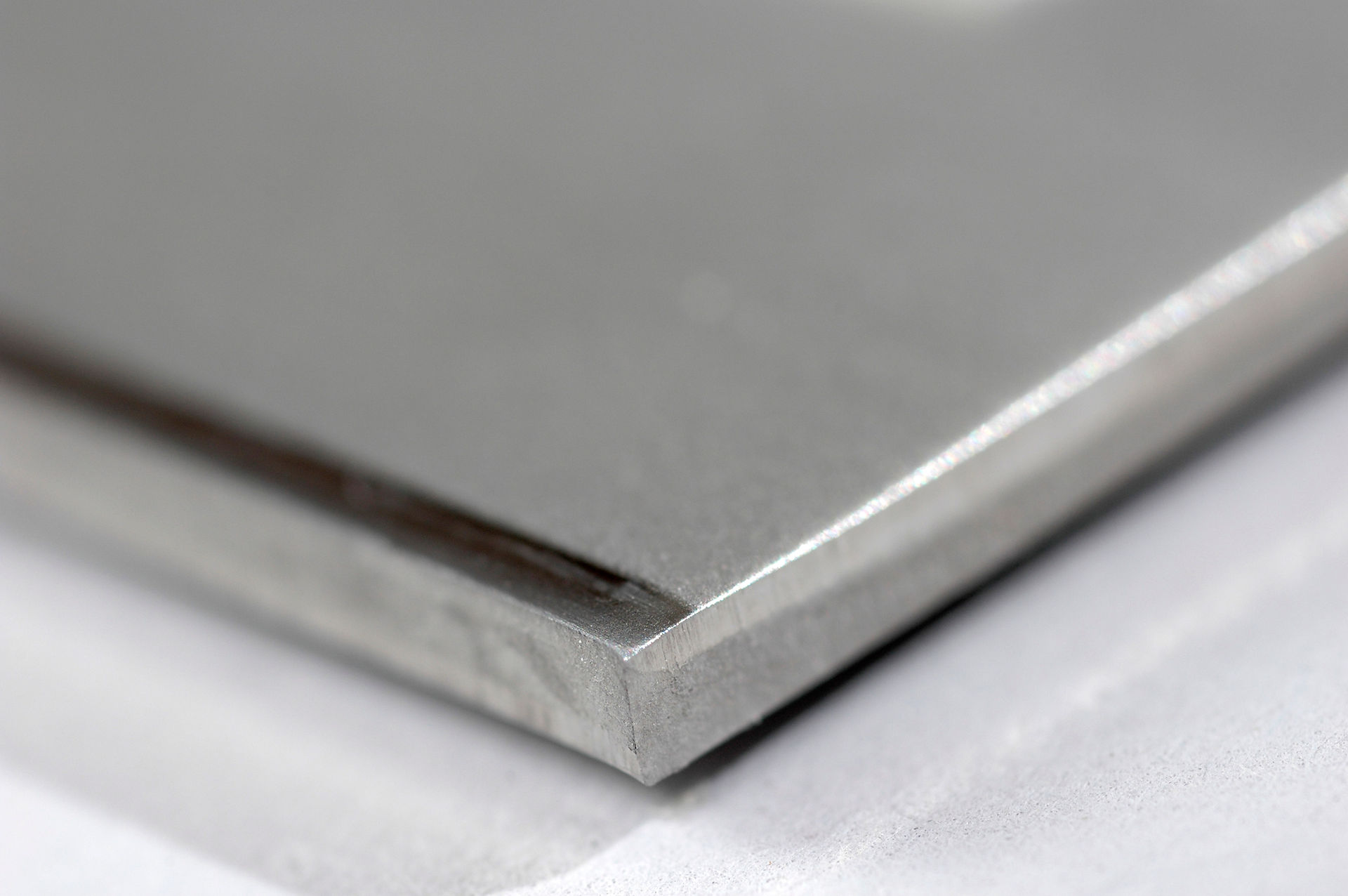

Equipment to manufacture and customized new complete cathode plates, according to each client specifications and requirements. Complete and new cathode plates production includes the sheet, hanger bar, edge strips and V-groove cut or third bottom edge strip.

-

Equipment to repair and give maintenance to used cathode plates, also based on each client´s requirements.

It is used to perforate the edges of the plate to guarantee the quality and perfect attachment of the permanent edge strip.

It makes the V-groove cut at the bottom edge of the plate, if required by the customer.

It is used during the final manufacturing phase to straighten and remove all tensions from the plate, assuring its verticality.

It is used to perforate the edges of the plate to guarantee the quality and perfect attachment of the permanent edge strip.

For new cathode plates

We have different machines and equipment to manufacture and customize new cathode plates.

Our annual production capacity is 200 000 plates.

This equipment cosists of:

Automated CNC machine

Automated V-groove unit

Automatic edge strip production line

Straightening and tension removal unit

Corner edge strip machine

Laser welding unit

To read more about them click on each picture

This medium size unit perforates the edges of the plates that have hanger bars. It can be set-up according to each plate dimensions and requirements.

This unit is used to extrude the permanent edge strip directly onto the side and bottom edges of the plate.

This unit removes all tensions of the plate after all maintenance process phases. It also assures the verticality and straightness of the plate.

This medium size unit perforates the edges of the plates that have hanger bars. It can be set-up according to each plate dimensions and requirements.

For repair and maintenance

These machines are used to give maitenance for used cathode plates with or without welded hanger bars.

They can be sold as a complete maintenance package "Cathodex Workshop" or individually.

This equipment cosists of:

Perforation unit

Permanent edge strip manufacturing machine

Automated brushing unit

Corner edge strip unit

V-groove repairment unit

Straightening and tension removal unit

To read more about them click on each machine picture.