Characteristics and Benefits of Cathodex® Technology

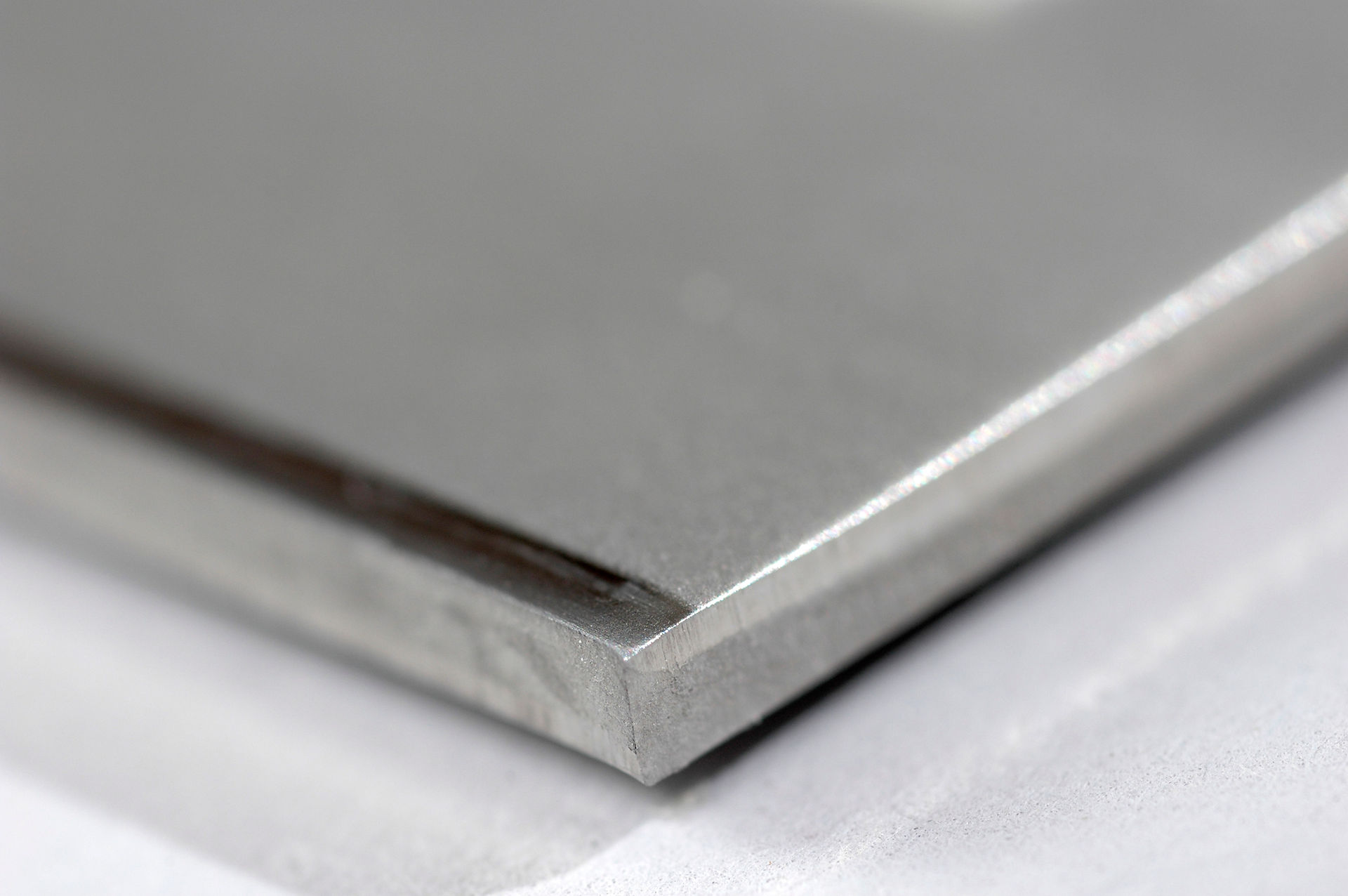

Cathodex edge strips are extruded directly to a pre-heated plate, using a patented welding technology.

This method heps to eliminate any space left between the plate and the edge strips, avoiding the growth of copper, nickel or zinc on top or under the edge strips.

It facilitates the stripping process. It does not detach off the plate, neither do breaks.

Significant costs savings when using Cathodex permanent edge strips.

Long lasting operational lifetime of the edge strips of up to 3 years without the need of continuos maintenance to the plates or change of egde strips.

We furnish the plates with 2 or 3 edge strips, sealing the corners perfectly with the same extruding method. We customize according to client´s requirements

![titaani4[2]](https://static.wixstatic.com/media/2352a5_8ff17c46b7a343a3a089fbc1f34c00f3.jpg/v1/fill/w_250,h_166,al_c,q_90,enc_auto/2352a5_8ff17c46b7a343a3a089fbc1f34c00f3.jpg) |  |  |  |  |

|---|

WE OFFER:

-

2 years limited guarantee for permanent edge strips in stainless steel and titanium plates.

-

18 months guarantee for permanent edge strips in aluminium plates.

The material used to manufacture the edge strips can be:

> Polipropylene PP

> Polyethylene PEH

> For aluminum different solutions are

offered.

The edges of the stainless steel and titanum plates

are perforated to guarantee the perfect attachment of the edge strips onto the plate.

Nowadays Cathodex technology is used in: Finland, Mexico, Zambia, Spain, Japan, Democratic Republic of the Congo, Chile, and China.